China JRT Rewinder Line factory wholesale

- BAOSUO

- China

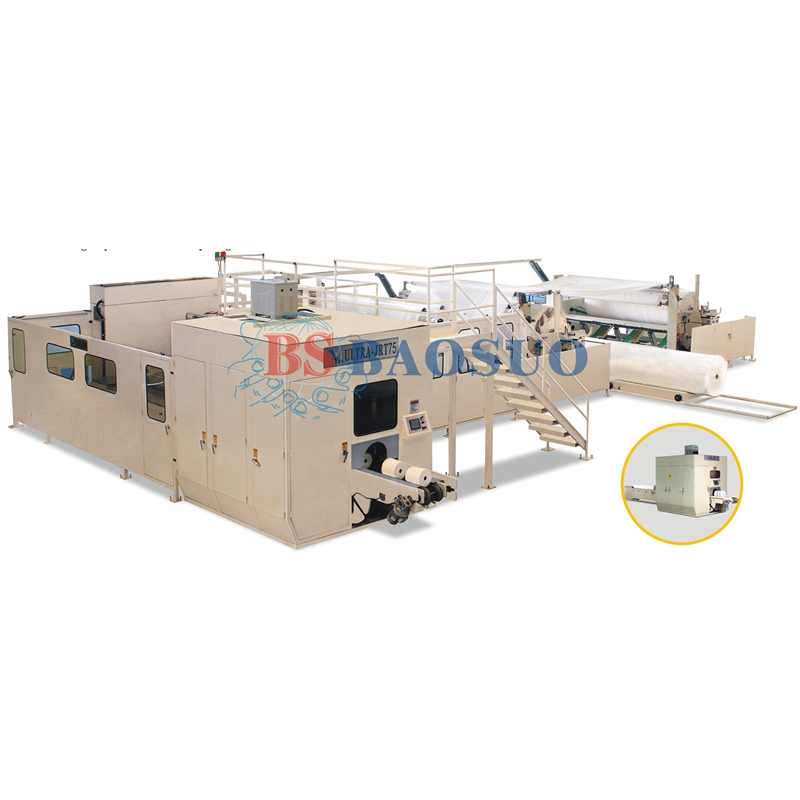

1. Stoble production speed up to 400m/min, Mitsubishi PLC;

2, Made by quality steel, with compact structure;

3, Flexible in various production specifications. Limination unit, single embossing unit and double embossing unit are optional;

4, Ladder available for manually load cores;automaticlly core feeding while rewinding;

5, Automatic core fededing, web cutting, and blowing;

6. Web tension real-time monitoring and precise adusting;

7. Airbag pressurization controlled edge embossing unit is optional

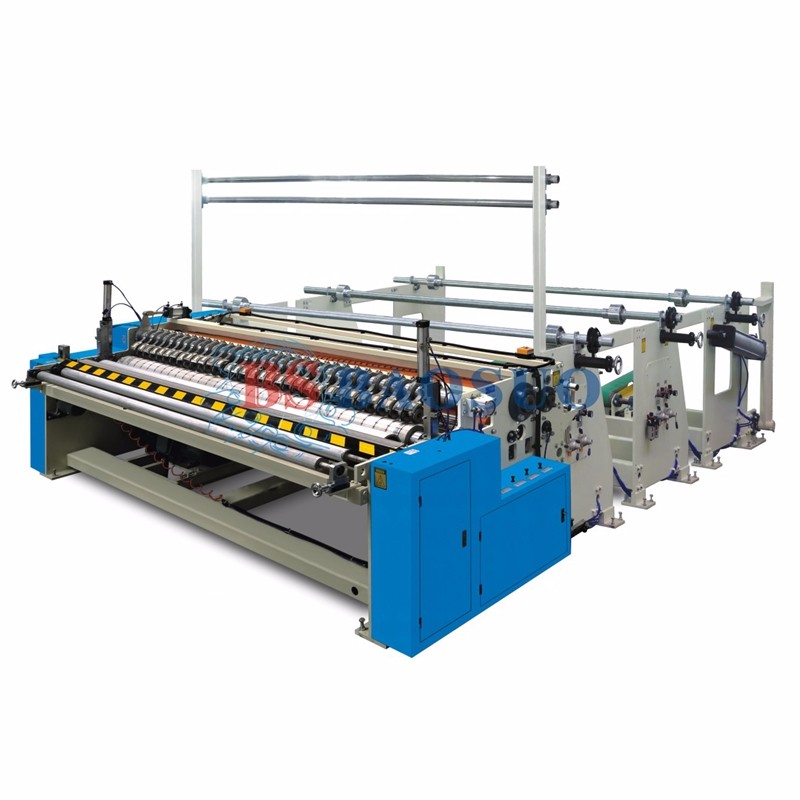

YD-C High Speed Automatic Cycling JRT Rewinder Line

1. Stoble production speed up to 400m/min, Mitsubishi PLC;

2, Made by quality steel, with compact structure;

3, Flexible in various production specifications. Limination unit, single embossing unit and double embossing unit are optional;

4, Ladder available for manually load cores;automaticlly core feeding while rewinding;

5, Automatic core fededing, web cutting, and blowing;

6. Web tension real-time monitoring and precise adusting;

7. Airbag pressurization controlled edge embossing unit is optional

YD-C 400 High Speed Automatic Cycling JRT Rewinder Line | |

Model | YD-C400 |

Production Speed | 400m/min |

Paper width | 3600mm to360000mm |

Jumbo roll diameter | Φ2500mm up to Φ2500mm |

Finished roll diameter | Φ180 ~ 350 mm |

Unwind stand | 1 ,2 or 3 unwind stands |

Tail sealer | Automatic |

Embosser | Single or double embosser |

Driving system | Independent drive |

Option | Edge embossing/Lamination system |