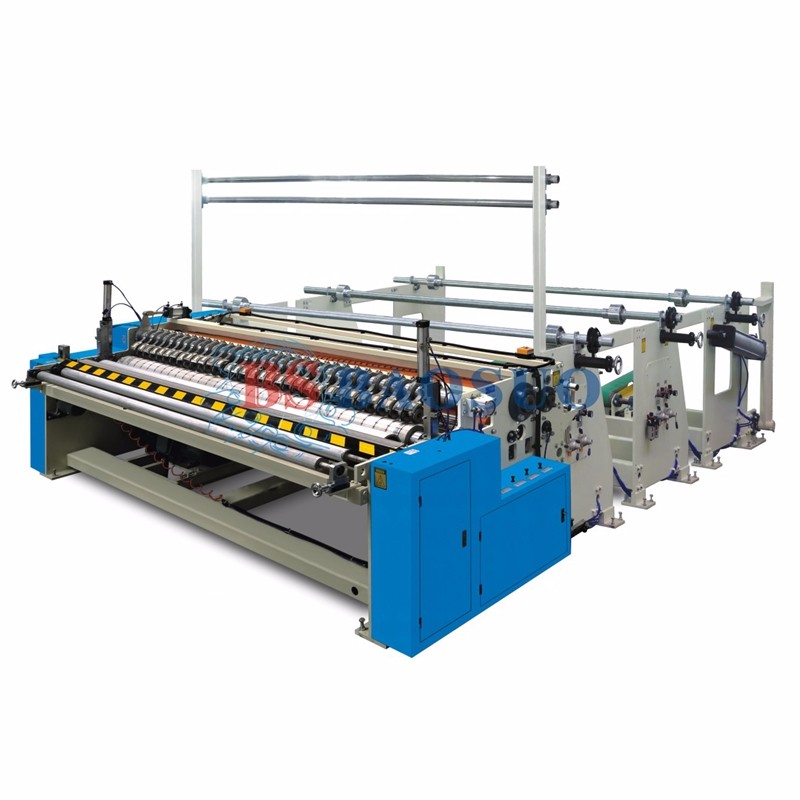

China JRT Rewinder Line factory manufacture

- BAOSUO

- China

1.Stable production speed up to 350 m/min;

2.Complete warning system and powerful integrated control system, supports remote terminal connection and detection;

3.Flexible and easy handling independent motor drive for each function unit;

4.Straight in machine web cutting, precise log diameter control system is accurate and easy operating;

5.Servo control perforation to secure accurate and stable sheet and pitch, and pitch is adjustable;

6.Edge embossing bottom roll is coated with alloy to achieve surface hardness 70HRC ensure durability. Customized edge embossing pattern is carved on 6408 bearing to ensure its quality;

7.Each unwind back stand is equipped with web tension control system to secure real time monitoring and web tension precise adjustment;

8.Mitsubishi or Siemens PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection,and accurate signal feedback;

9.Embossing lamination unit, embossing unit and automatic core feeding systems are optional.

YD-PL400E Non-Stop JRT Rewinder Line

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

PF-PL400E | |||

Model | 1800 | 2200 | 2900 |

Jumbo roll width | 1750 mm | 2150 mm | 2850 mm |

Jumbo roll diameter | 2000 ~ 3000 mm | ||

Jumbo roll core size | Φ76.2 mm (Other sizes are available) | ||

Finished log core diameter | 170 ~ 300 mm | ||

Core size | 76.2 mm | ||

Perforation | 4 pieces spiral upper perforation knife, improve the durability | ||

Rewind type | Non-stop | ||

Parameter set-up | HMI | ||

Control system | PLC, Inverter, Optical-elecro-mechanic integration | ||

Web tension control | Encoder, PLC, Inverter | ||

Machine speed | 350 m/min | ||

Backstand | 1 ~ 3 ply (To be confirm by client), Independent drive | ||

Option | |||

Embossing unit | Steel to rubber embossing, point to point embosser with lamination, nested embosser with lamination, DECO embosser with lamination | ||

Edge embossing unit | Steel to steel | ||

Printing unit | 1 ~ 2 colors (customer provides pattern) | ||

1. Stable production speed up to 350 m/min;

2. Complete warning system and powerful integrated control system, supports remote terminal connection and detection;

3. Flexible and easy handling independent motor drive for each function unit;

4. Straight in machine web cutting, precise log diameter control system is accurate and easy operating;

5. Servo control perforation to secure accurate and stable sheet and pitch, and pitch is adjustable;

6. Edge embossing bottom roll is coated with alloy to achieve surface hardness 70HRC ensure durability. Customized edge embossing pattern is carved on 6408 bearing to ensure its quality;

7. Each unwind back stand is equipped with web tension control system to secure real time monitoring and web tension precise adjustment;

8. Mitsubishi or Siemens PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection,and accurate signal feedback;

9. Embossing lamination unit, embossing unit and automatic core feeding systems are optional.