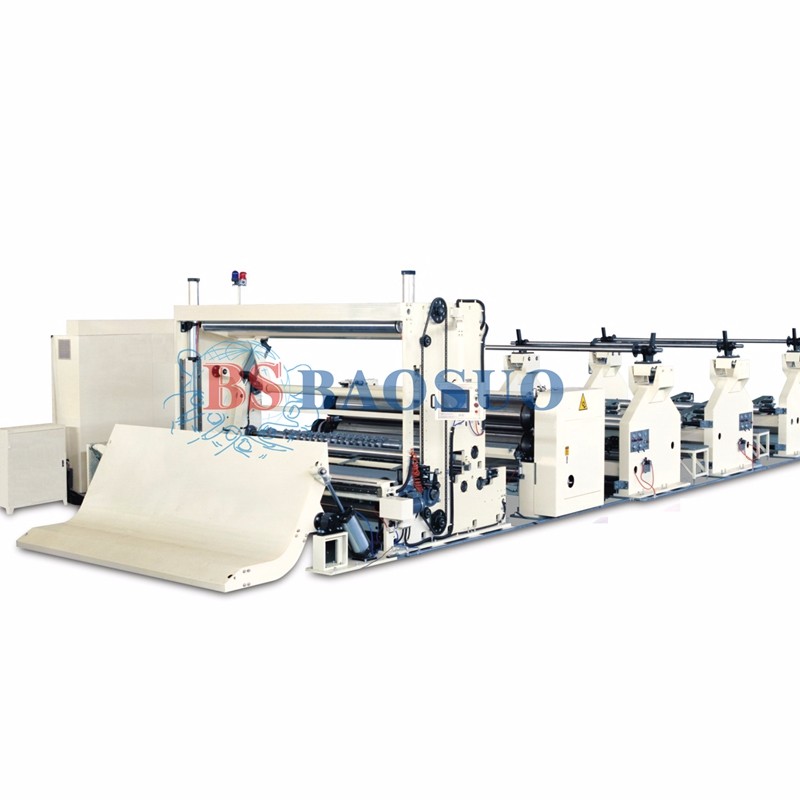

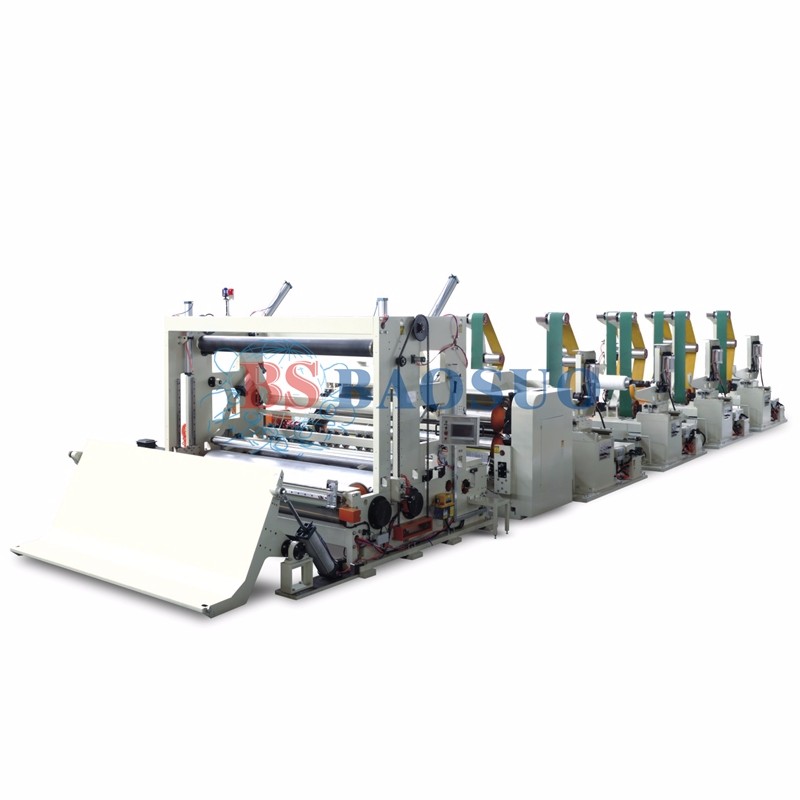

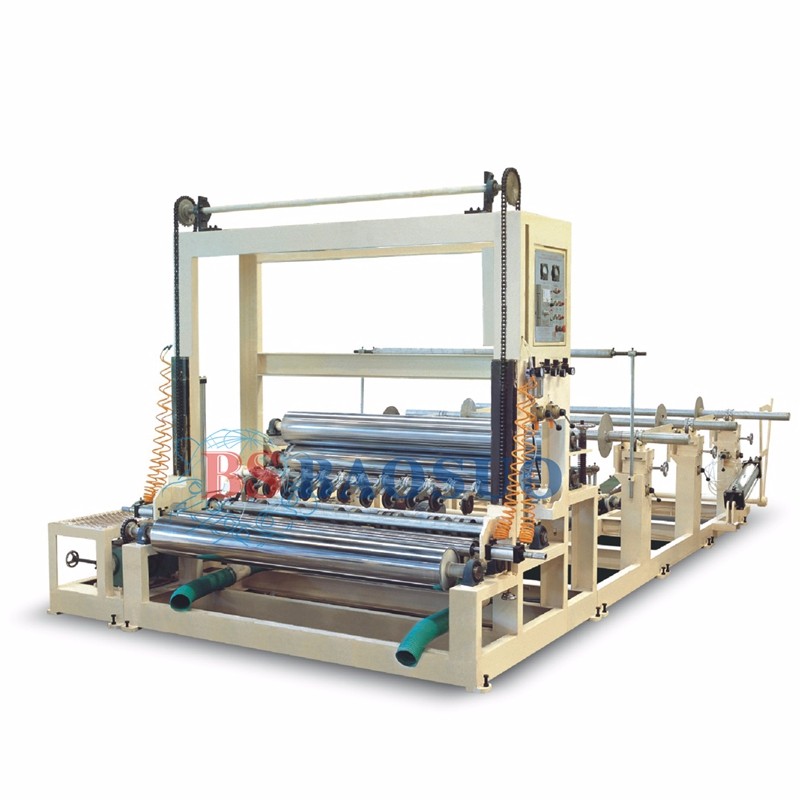

700m/min Automatic High Speed Jumbo Roll Slitting Rewinder

- BAOSUO

- China

Brief introduction:

1.Stable production speed up to 750 m/min;

2.Made by quality steel with compact structure;

3.Independent servo motor drive, precise and efficient;

4.Unique control technology, the jumbo roll surface flatness can reach ±0.5 mm;

5. Machine efficiency improved by 15% by adding automation functions in core feeding, web cutting and blowing;

6. High precision closed-loop motion control system consisted of PLC and frequency convertor;

7. Each unwind backstand is equipped with web tension control system to secure real time monitoring and web tension precise adjustment;

8. Dual airbag pressurization controlled calendaring unit.

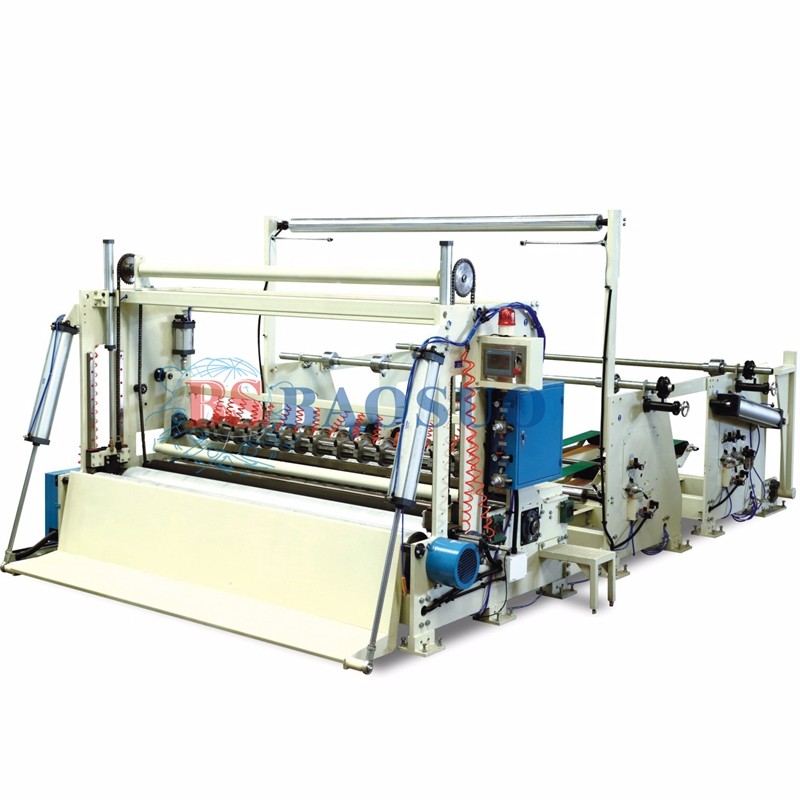

PF-EA Automatic High Speed Jumbo Roll Slitting Rewinder

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

PF-EA | |||

Machine model | 3000 | 3600 | Other model to order |

Jumbo roll width | 2950 | 3550 | Other model to order |

Machine speed | 700 ~ 800 m/min | ||

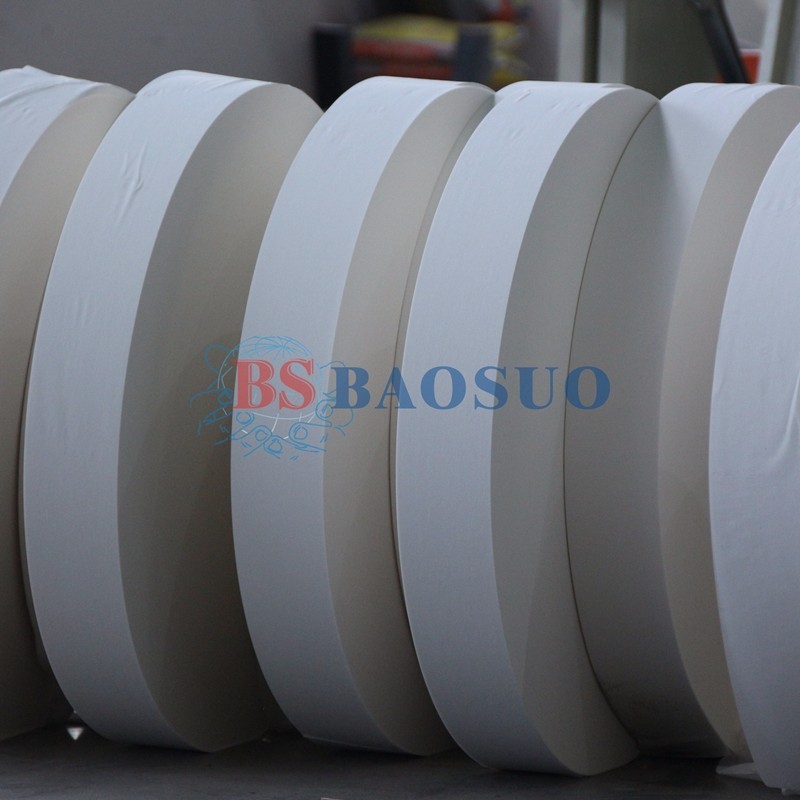

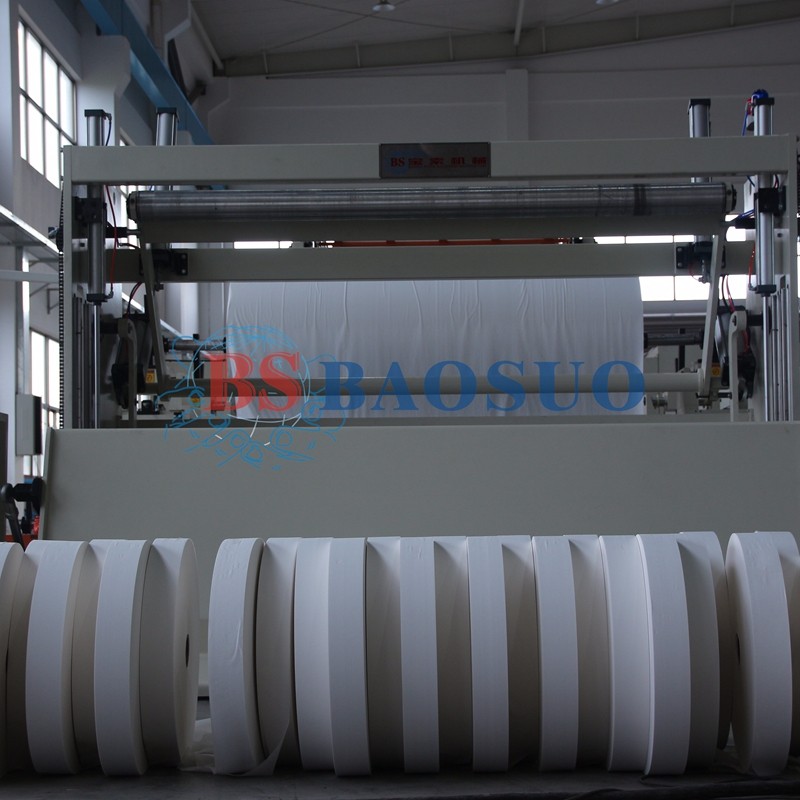

Finished roll diameter | ≤ 1500 mm | ||

Slitting width | Min. 180 mm, max. to jumbo roll width | ||

Finished roll core diameter | Φ76.2 mm (Other size to order) | ||

Jumbo roll diameter | ≤ 2200 mm (Other size to order) | ||

Jumbo roll core diameter | Φ76 mm (Other size to order) | ||

Rewinding system | Pneumatic timing rewinding | ||

Slitting system | Independent pneumatic slitter | ||

Discharging system | Automatic discharging | ||

Programmable controller | LCD and LCD | ||

Option | |||

Calendering unit | Steel to steel, steel to rubber | ||

Tail collection system | Unwind stand: 1 ~ 4 ply (To order) | ||

Import brand upper cutting system | Paper for slit sanitary textile | ||

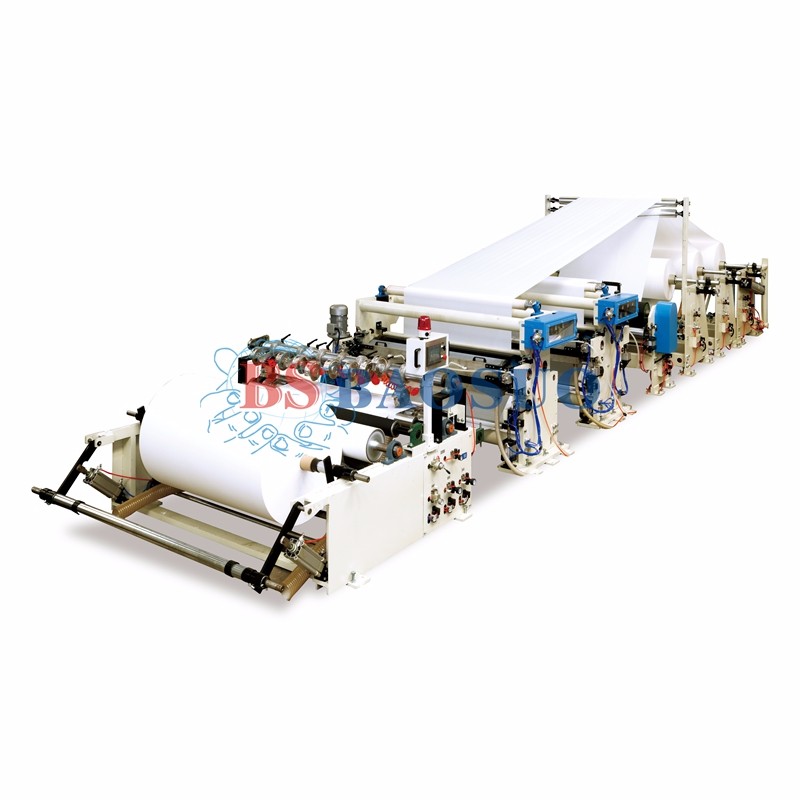

Brief introduction:

1. Stable production speed up to 750 m/min;

2. Made by quality steel with compact structure;

3. Independent servo motor drive, precise and efficient;

4. Unique control technology, the jumbo roll surface flatness can reach ±0.5 mm;

5. Machine efficiency improved by 15% by adding automation functions in core feeding, web cutting and blowing;

6. High precision closed-loop motion control system consisted of PLC and frequency convertor;

7. Each unwind backstand is equipped with web tension control system to secure real time monitoring and web tension precise adjustment;

8. Dual airbag pressurization controlled calendaring unit.