China toilet paper equipment wholesale supplier

- BAOSUO

- China

Brief Introduction:

1.Integrated with core and coreless rewinding, applied rewinding for several invention patents;

2.Stable production speed: up to 250 m/min for rolls with core, 180 m/min for coreless roll;

3.High automation, integrated control system has strong extension function and supports remote terminal connection and detection;

4.Patented vacuum suction technology for coreless roll rewinding to secure rewinding quality and production stability;

5.Non-stop rewinding with tissue length error±1 sheet;

6.Equipped with edge embossing unit, 60 embossing wheel for regular web width;

7.Rear doctor blade for web cutting and core gluing,perfect match product with embossing lamination;

8.PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection, and accurate signal feedback.

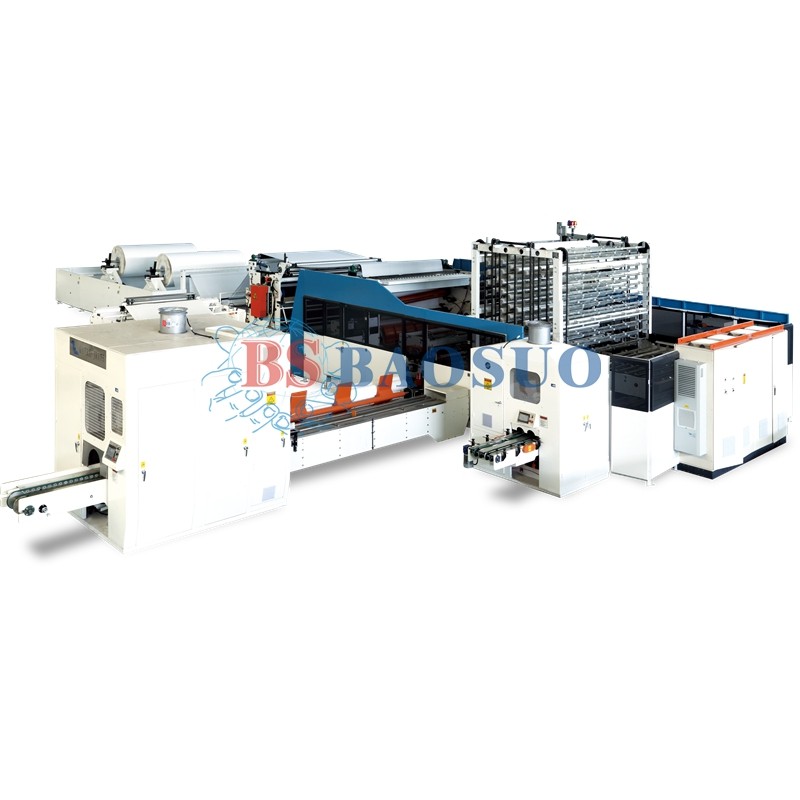

YD-PL250C Non-stop Toilet Roll / Kitchen Towel Rewinder Line

Min. Order: 1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

Product description:

REWINDING SYSTEM | |

Design speed | 250 m/min |

With core speed | 220 m/min |

Coreless speed | 180 m/min |

Jumbo roll width | 1750 ~ 3550 mm |

Jumbo roll diameter | ≤φ1500 (>1500 To be order) |

Jumbo roll core size | φ76.2 mm (Other sizes are available) |

Finished log diameter | φ70 ~ φ135mm |

Perforation | 4 pieces spiral upper perforation knife |

Rewinding way | Non-stop |

Parameter set-up | HMI |

Control system | PLC, Inverter, integration of mechanics, electrics and photo |

Web tension system | Encoder, PLC, Inverter |

Option | |

Unwind stand | 1 ~ 3 Ply (To be confirmed by client, independent drive) |

Embossing unit | Steel to rubber, point to point embossing, lamination unit |

Edge embossing unit | Steel to steel |

Printing unit | 1 ~ 2 colors (Customers provides pattern) |

Brief Introduction:

1. Integrated with core and coreless rewinding, applied rewinding for several invention patents;

2. Stable production speed: up to 250 m/min for rolls with core, 180 m/min for coreless roll;

3. High automation, integrated control system has strong extension function and supports remote terminal connection and detection;

4. Patented vacuum suction technology for coreless roll rewinding to secure rewinding quality and production stability;

5. Non-stop rewinding with tissue length error±1 sheet;

6. Equipped with edge embossing unit, 60 embossing wheel for regular web width;

7. Rear doctor blade for web cutting and core gluing,perfect match product with embossing lamination;

8. PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection, and accurate signal feedback.