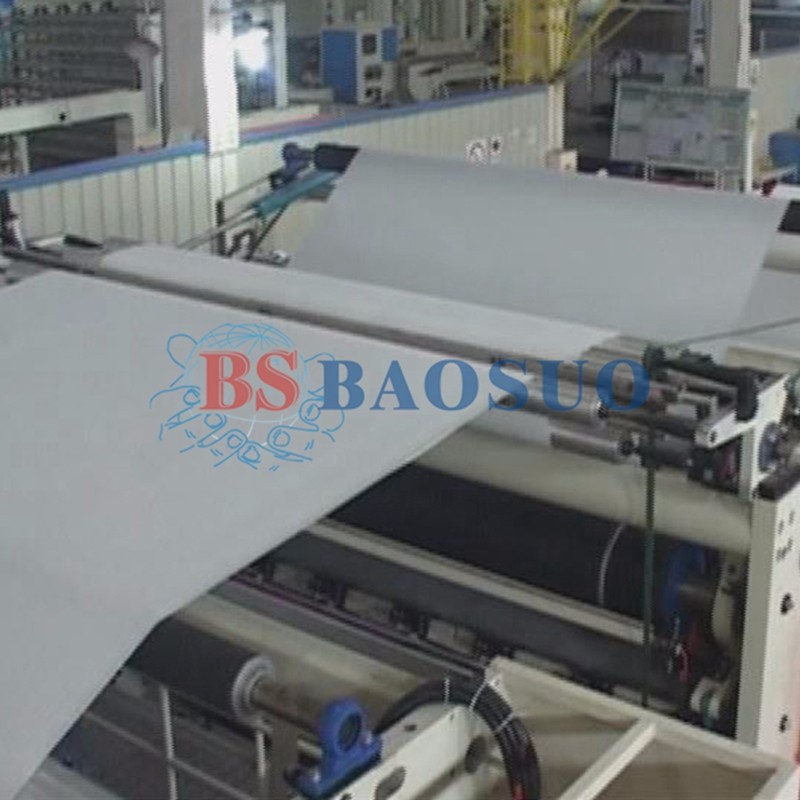

China JRT rewinder machine line wholesale customized

- BAOSUO

- China

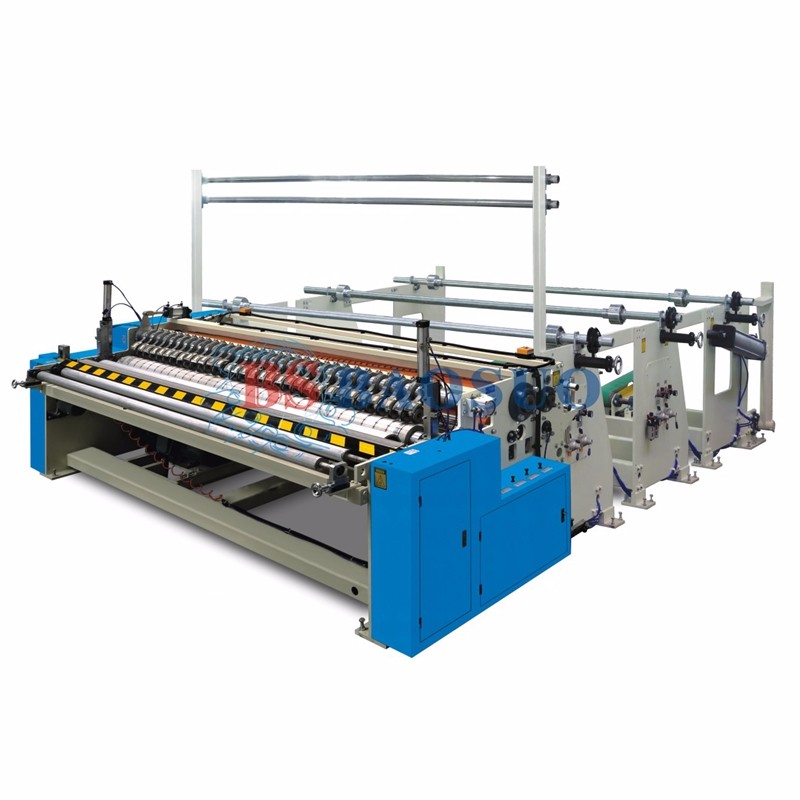

1.Stable production speed up to 500 m/min;

2.Complete warning system and powerful integrated control system, supports remote terminal connection and detection;

3.Flexible and easy handling independent motor drive for each function unit;

4.Straight in machine web cutting, precise log diameter control system is accurate and easy operating;

5.Servo control perforation to secure accurate and stable sheet and pitch, and pitch is adjustable;

6.Edge embossing bottom roll is coated with alloy to achieve surface hardness 70HRC ensure durability. Customized edge embossing pattern is carved on 6408 bearing to ensure its quality;

7.Each unwind back stand is equipped with web tension control system to secure real time monitoring and web tension precise adjustment;

8.Mitsubishi or Siemens PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection,and accurate signal feedback;

9.Embossing lamination unit, embossing unit and automatic core feeding systems are optional.

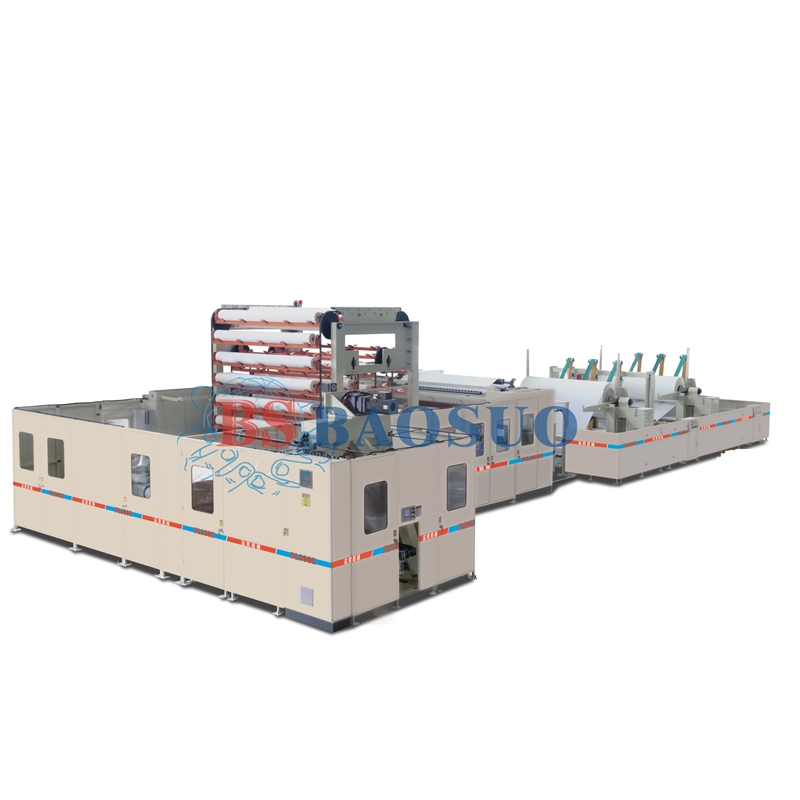

YD-PL600E Non-Stop JRT Rewinder Line

Min. Order:1

Payment term: T/T

Delivery time: 2 ~ 6 months

Shipping port: Foshan

PF-PL600E | |

Model | 2900 (Other size to be specified) |

Jumbo roll width | 2850 mm |

Jumbo roll diameter | 2000 ~ 3000 mm |

Jumbo roll core size | Φ76.2 mm, shaftless type (To order) |

Finish log core diameter | Max. Φ1500 mm |

Jumbo roll core diameter | φ170 ~ 300 mm |

Finish log core diameter | 76.2 mm |

Perforation | 6 pieces spiral upper perforation knife, improve the durability |

Rewind type | Non-stop |

Parameter set | HMI |

Rewind alternation | Core insert (Patent protection) |

Control system | PLC, Inverter, Optical-elecro-mechanic integration |

Tension control | Encoder, PLC, Inverter |

Machine speed | 600 m/min

|

Backstand | 1 ~ 3 ply (To be confirm by client), Independent drive |

T15 Tail sealer | Patent protection |

Tail length | 5 ~ 30 mm, adjustable |

JAC40 ACCUMULATOR | |

Log diameter | 170 ~ 300 mm |

Effective log Qty | 40 pieces |

Speed | 20 logs/min |

ULTRA-JRT75 LOG SAW (Option) | |

Production speed with 1000 mm Blade diameter | 60 cuts/min

|

Max. log diameter | 300 mm |

Min. log diameter | 180 mm |

Min. cutting length | 90 mm |

Max. cutting length | 280 mm |

Saw in-feed | Single in-feed |

Max. Log length | 3250 mm |

*Other specifications are available to your requirement. | |

JBS60 BAND SAW (Option) | |

Model | JBS60 |

Feeding channel | Single |

Type | Band saw up and down reciprocal type |

Driving system | Servo |

Log outside diameter | 150 ~ 310 (Please appoint) |

Grinding system | Auto feeding, parameter can be set or the control panel |

Cutting length | 90 ~ 280 mm |

Cutting length tolerance | ≤ 2 mm |

Log length | 2850 mm |

Design speed | 50 cuts/min |

Cutting vertical tolerance | ≤ 1 mm |

Electric control system | SIEMENS |

Production speed | ≤ 30 cuts/min |

1. Stable production speed up to 500 m/min;

2. Complete warning system and powerful integrated control system, supports remote terminal connection and detection;

3. Flexible and easy handling independent motor drive for each function unit;

4. Straight in machine web cutting, precise log diameter control system is accurate and easy operating;

5. Servo control perforation to secure accurate and stable sheet and pitch, and pitch is adjustable;

6. Edge embossing bottom roll is coated with alloy to achieve surface hardness 70HRC ensure durability. Customized edge embossing pattern is carved on 6408 bearing to ensure its quality;

7. Each unwind back stand is equipped with web tension control system to secure real time monitoring and web tension precise adjustment;

8. Mitsubishi or Siemens PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection,and accurate signal feedback;

9. Embossing lamination unit, embossing unit and automatic core feeding systems are optional.