paper machine

-

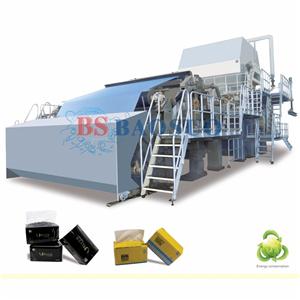

1000m/min Suction Former Tissue Machine

ADVANCED TECHNOLOGY -- TAKE THE LEAD Mr. Sasaki is the founder of the SF series Suction Former Yankee tissue machine. Along with the era of rapid development, the human being reinforces the concept of environmental protection and scientifically using the resources on earth. The subject of how to get a solution to tissue production for not only realizing high efficiency and low energy consumption, but also adapting various raw materials and producing all kinds of high quality products,is always our pursuing goal, which penetrates into our design principle and service purposes. After decades of drilling and precipitation, the core technical team of Sasaki has sublimed their technologies and applied each scientific research gain into Baotuo series of tissue machines, fully performing excellence in every production link, making our customer heading list in the market competition, truly obtaining substantial benefits and winning business opportunities. FEATURES TISSUE MACHINE 1.Core technique from Japan Sasaki 2.Various raw materials adaptable 3.Applicable for wide range of basic weight 4.Energy saving and environment-friendly 5.Low running cost 6.High automation 7.Intelligent easy operation 8.Quick start-up

Email Details -

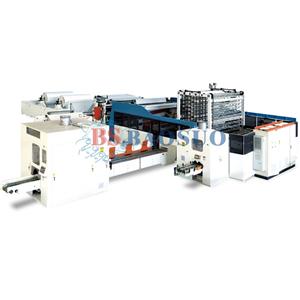

600m/min Non-Stop Toilet Roll Kitchen Towel Machine

Brief Introduction: 1.Stable production speed up to 500 m/min; 2.Complete warning system and powerful integrated control system, supports remote terminal connection and detection; 3.Flexible and easy handling independent motor drive for each function unit; 4.Straight in machine web cutting.precise log diameter control system is accurate and easy operating; 5.Servo control perforation to secure accurate and stable sheet and pitch, and pitch is adjustable; 6.Edge embossing bottom roll is coated with alloy to achieve surface hardness 70HRC ensure durability. Customized edge embossing pattern is carved on6408 bearing to ensure its quality; 7.Each unwind back stand is equipped with web tension control system to secure real time monitoring and web tension precise adjustment; 8.Mitsubishi or Siemens PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection, and accurate signal feedback; 9.Embossing lamination unit, embossing unit and automatic core feeding systems are optional.

Email Details -

1200m/min Suction Former Tissue Machine

ADVANCED TECHNOLOGY -- TAKE THE LEAD Mr. Sasaki is the founder of the SF series Suction Former Yankee tissue machine. Along with the era of rapid development, the human being reinforces the concept of environmental protection and scientifically using the resources on earth. The subject of how to get a solution to tissue production for not only realizing high efficiency and low energy consumption, but also adapting various raw materials and producing all kinds of high quality products,is always our pursuing goal, which penetrates into our design principle and service purposes. After decades of drilling and precipitation, the core technical team of Sasaki has sublimed their technologies and applied each scientific research gain into Baotuo series of tissue machines, fully performing excellence in every production link, making our customer heading list in the market competition, truly obtaining substantial benefits and winning business opportunities. FEATURES OF TISSUE MACHINE 1.Core technique from Japan Sasaki 2.Various raw materials adaptable 3.Applicable for wide range of basic weight 4.Energy saving and environment-friendly 5.Low running cost 6.High automation 7.Intelligent easy operation 8.Quick start-up

Email Details -

Hot

YH-FG Automatic Facial Tissue Production Line

YH-FG Automatic Facial Tissue Converting Machine 1. Production speed: 130m/min, stacking speed ≥15log/min, width: 1500-3700mm; 2. The first piece of tissue is folded to the middle automatically, matching the conveyance flip system, and the finished product is beautiful and square; 3. The facial tissue machine is perfectly matched with high value-added products such as position embossing, glue free lamination, 4D embossing and water lamination; 4. Full servo automatic stacking, integrated control, high degree of automation, with function of remote detection; 5. Electromechanical integrated control technology, automatic detection, accurate feedback; 6. Upgraded arc stacking system to improve quality and efficiency.

facial tissue folding machine tissue paper machine facial tissue production line tissue converting machineEmail Details -

1100m/min Crescent Former Tissue Machine

Brief Introduction of BC-1100 Crescent Former Tissue Machine 1.Top choice for medium and small-sized enterprises, as well as old factory renovations. 2.Less land occupation 3.Economic and energy-saving 4.Paper web forming uniformity 5.High tensile strength 6.Small web basic weight deviation 7.Intelligent operation,easy maintenance 8.Quick start-up

Email Details -

Hot

1300-1600m/min Crescent Former Tissue Machine

Brief Introduction of BC-1300/1600 Crescent Former Tissue Machine 1.Steady running 2.Low running cost 3.Paper web forming uniformity 4.High tensile strength 5.Small web basic weight deviation 6.Large output, with daily capacity of each machine up to 135 tons! 7.Intelligent operation, easy maintenance 8.Quick start-up

Email Details -

Hot

1500mm - 2200mm Auto Transfer Automatic Facial Tissue Production Line

Brief introduction(YH-FD Automatic Facial Tissue Converting Machine): 1.Production Speed: 90 ~ 100 m/min, Stacking speed ≧ 10log/min; 2.Automatic stacking instead of which by manual, with width available: 1500 ~ 2900mm; 3.High degree of automation, powerful extended function in integrated control system, with function of remote detection; 4.Simple structure, easy operation and maintenance; 5.Stable operation, high production efficiency; 6.The facial tissue machine has an automatic end stacking function; 7.Electromechanical integrated control technology, automatic detection, accurate feedback.

facial tissue folding machine tissue paper machine facial tissue production line tissue converting machineEmail Details -

Hot

450m/min Non-Stop Rewinder Line

Brief Introduction: 1.Integrated with core and coreless rewinding, applied rewinding for several invention patents; 2.Stable production speed: up to 450 m/min; 3.Complete warning system and powerful integrated control system, supports remote terminal connection and detection; 4.Straight in machine web cutting, precise log diameter control system is accurate and easy operating; 5.Patented vacuum suction technology for coreless roll rewinding to secure rewinding quality and production stability; 6.Flexible and easy handling independent motor drive for each function unit; 7.Rear doctor blade for web cutting and core gluing, perfect match product with embossing lamination; 8.Equipped with edge embossing unit, 60 embossing wheel for regular web width; 9.Applicable to various web tensions of different jumbo roll grades; 10.PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection, and accurate signal feedback.

Email Details -

Hot

250m/min Non-Stop Rewinder Line

Brief Introduction: 1.Integrated with core and coreless rewinding, applied rewinding for several invention patents; 2.Stable production speed: up to 250 m/min; 3.Complete warning system and powerful integrated control system, supports remote terminal connection and detection; 4.Straight in machine web cutting, precise log diameter control system is accurate and easy operating; 5.Patented vacuum suction technology for coreless roll rewinding to secure rewinding quality and production stability; 6.Flexible and easy handling independent motor drive for each function unit; 7.Rear doctor blade for web cutting and core gluing, perfect match product with embossing lamination; 8.Equipped with edge embossing unit, 60 embossing wheel for regular web width; 9.Applicable to various web tensions of different jumbo roll grades; 10.PLC, large screen HMI, opto-mechatronics control technology, automatic web break detection, and accurate signal feedback.

Email Details